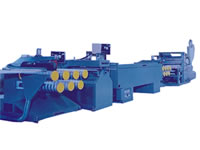

M. AJAY offer tape lines for manufacturing PP/HDPE flat tapes, fibrillated tapes and serrated tapes to produce Woven sacks, Tarpaulins, FIBCs(Jumbo Bags), ropes, stitching threads, pp fibrillated cable filler etc.. M.AJAY offers plants ranging from 65 mm extruders to 90 mm extruders with peak output capacities of 65 kgs/hr to 350 kgs/hr.

Read More –>Tape Stretching Line

Salient Features

-

Grooved Feed Barrels and Barrier Screws for proper mixing and higher productivity.

-

Integral thrust bearing mounted helical gear box.

-

Needle density up to 30 needles/cm. in two rows.

-

Continuous Screen Changer.

-

Coat Hanger type T-Die with adjustable lip.

-

Hot Air Oven/ Hot Plate.

-

Movack type Holding unit and Combined stretching and annealing unit for longer life and vibration free operation

-

Fully synchronized Plant with AC frequency drive for Extruder, Goddets with master control.

-

PID temperature control Panel.

-

Power saving Tape extractor with vacuum suction box.

High Output Models

|

Economy Models For PP Cable Filler/PP Ropes.

|